positive displacement pump vs centrifugal pump how to Choosing the right pump is key for top performance and efficiency in fluid handling. We’ll look at positive displacement pumps and centrifugal pumps, focusing on their strengths and uses. Knowing the differences between these pumps is vital for making the right choice in different situations.

By comparing pump performance, we aim to help you find the best option for your needs. This comparison will guide you in selecting the most suitable pump for your specific requirements.

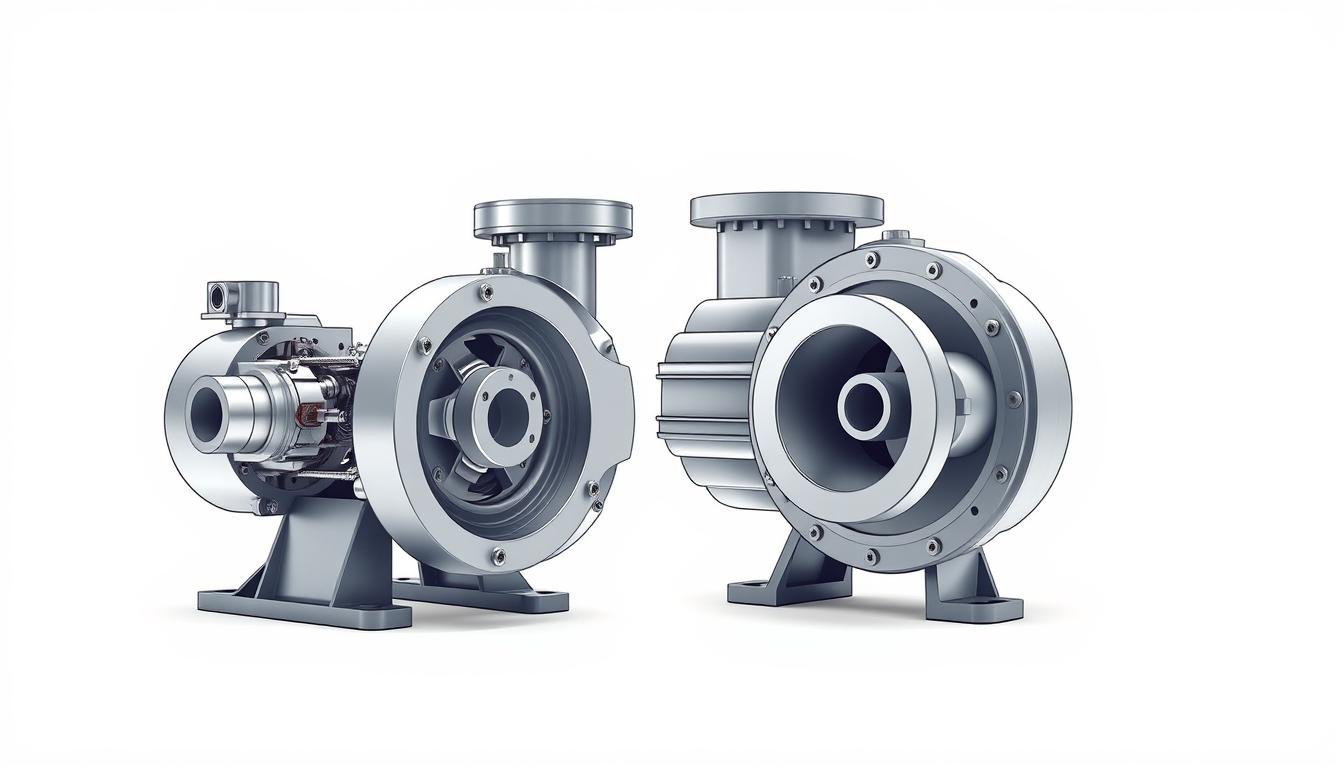

Understanding Centrifugal Pumps:

A centrifugal pump is a machine that moves fluids by changing mechanical energy into fluid energy. It works by using an impeller’s spin. This impeller is inside a casing and makes the fluid move outward. This movement creates a pressure difference that pulls more fluid into the pump.

The main parts of a centrifugal pump are the impeller and volute. The impeller gives the fluid kinetic energy. The volute then turns this energy into pressure as the fluid leaves the pump.

Centrifugal pumps are used in many ways. They are key in water supply systems for steady flow. They also help in HVAC systems by moving fluids for temperature control. In chemical processing, they efficiently handle large amounts of liquid.

Understanding Positive Displacement Pumps

A positive displacement pump works by trapping a fixed amount of fluid. Then, it forces this fluid into the discharge line. This method efficiently moves fluid, no matter the system pressure. Knowing how these pumps work is key, as they offer consistent flow and pressure. They’re great for handling thick and abrasive fluids.

There are many types of positive displacement pumps. Gear pumps use interlocking gears for a steady flow. Diaphragm pumps use a flexible membrane for clean suction. Piston pumps create high pressure through a reciprocating motion, ideal for high-pressure needs.

Positive displacement pumps have many uses. In food processing, they keep things clean and handle different ingredients well. For oil transfer, they move thick fluids without damaging them. They also power hydraulic systems, making machines work better. Their wide range of uses shows their value in many industries.

Positive Displacement Pump vs Centrifugal Pump: Key Differences

It’s important to know the difference between positive displacement pumps and centrifugal pumps. Each has its own way of working, which affects how well they perform. Positive displacement pumps trap a set amount of fluid and push it out. Centrifugal pumps use spinning energy to push fluid out, drawing it in first.

Positive displacement pumps are great for fluids that are thick and need a steady flow. They work well even when the system pressure is high. Centrifugal pumps are better for fluids that flow easily and need to move a lot. But, they don’t do as well when the pressure is too high.

Looking at how reliable and easy to maintain these pumps are, positive displacement pumps win. They last longer and need less upkeep. But, they cost more to set up than centrifugal pumps. The choice depends on what you need in the long run and your budget.

| Aspect | Positive Displacement Pump | Centrifugal Pump |

|---|---|---|

| Flow Rate | Constant, irrespective of pressure | Varies with system pressure |

| Viscosity Handling | Best suited for high-viscosity fluids | Designed for low-viscosity fluids |

| Pressure Handling | Handles high pressures easily | Performance declines under high pressure |

| Maintenance | Generally lower over time | Higher maintenance requirements |

| Cost | Higher initial investment | Lower installation cost |

When to Use a Centrifugal Pump?

Deciding when to use a centrifugal pump involves knowing when it’s the best choice. These pumps are great for moving fluids that are not very thick. They work well with clean water and other light liquids.

They are also perfect when you need a lot of flow. Their design lets them handle big volumes efficiently.

It’s also important to think about the system’s operating conditions. Centrifugal pumps do best with steady flow and little pressure change. When choosing a pump, I look for systems that meet these needs.

They are often used in water supply, heating systems, and industrial processes.

Head requirement is another key factor. For systems needing low to moderate head, centrifugal pumps perform well. I look for systems that make the most of these pumps’ efficiency.

The system design should help the pump work smoothly. All parts need to work together well.

When to use a positive displacement pump?

Use a positive displacement pump when handling thick or viscous fluids like oils or syrups.

It is ideal for applications requiring accurate and consistent flow rates.

This type of pump works well in high-pressure, low-flow conditions.

It handles shear-sensitive materials gently without damage.

Positive displacement pumps can self-prime and lift fluids from lower levels.

They are suitable for industries like food, pharma, chemical, and oil & gas.

Conclusion

It’s important to know the differences between positive displacement and centrifugal pumps. Each has its own strengths and weaknesses. Positive displacement pumps are great for thick fluids or when you need exact flow rates. Centrifugal pumps work best for thin liquids and when you need a lot of flow.

Before choosing a pump, think about your fluid, pressure, and system needs. The right pump can make your fluid handling better and more efficient. Knowing the differences helps you make the best choice for your operations.

Choosing the right pump depends on your project’s needs. A careful selection leads to success and reliable systems. This approach ensures your fluid systems work well for a long time.

FAQ

Q: What is a centrifugal pump?

A: A centrifugal pump changes mechanical energy into fluid energy. It uses an impeller to speed up the fluid. Then, it directs the fluid into a diffuser or volute, turning the speed into pressure. This makes it great for moving lots of liquids.

Q: What is a positive displacement pump?

A: A positive displacement pump moves fluid by trapping a set volume and pushing it out. It’s good at handling thick fluids and high pressures. This makes it perfect for places where a steady flow is needed.

Q: When should I use a centrifugal pump?

A: Use a centrifugal pump for fluids like clean water. It’s best for high flow rates at low to moderate pressures. It’s great for water supply, HVAC, and chemical processing because it moves lots of fluid efficiently.

Q: When should I use a positive displacement pump?

A: Choose a positive displacement pump for thick fluids, precise flow control, or high pressures. It’s best for food processing, hydraulic systems, and oil transfer. It keeps flow consistent, which is important in these areas.

Q: What are the key differences between positive displacement pumps and centrifugal pumps?

A: Positive displacement pumps move a fixed volume with each cycle. Centrifugal pumps use speed and pressure to move fluid. This affects their flow rates, pressure handling, and efficiency. Positive displacement pumps are better for thick fluids, while centrifugal pumps work well with thin fluids.

Q: What are common applications for centrifugal pumps?

A: Centrifugal pumps are used in many places. They’re in municipal water systems, HVAC, chemical processing, and irrigation. They’re good at moving clean, non-corrosive fluids in large amounts, making them versatile.

Q: What types of positive displacement pumps are there?

A: There are many types of positive displacement pumps. You have gear pumps, diaphragm pumps, and piston pumps. Each is designed for specific tasks, like handling thick fluids or high pressure in hydraulic systems.