Compressors are key for powering tools, running refrigeration systems, and keeping industrial processes going. But, knowing the differences between types of compressors is vital. This includes understanding the main categories: Positive Displacement Compressors and Dynamic Compressors.

Ever been confused about choosing between a screw compressor and a centrifugal compressor? Or maybe you’re wondering about the difference between a compressor vs pump? This guide will clear up all your doubts. We’ll explain everything in simple terms, without losing any important technical details.

What is a Compressor?

A compressor is a machine that makes gas pressure go up by making its volume go down. Most often, it’s used for air, but it can also work with gases like nitrogen, helium, or refrigerants.

In our daily lives, we see compressors in many places:

- Air conditioning and refrigeration systems.

- Gas pipelines.

- Automotive garages (for pneumatic tools and tire inflation).

- Manufacturing plants.

- Aircraft engines.

The main idea is straightforward: a compressor takes in gas at low pressure, squeezes it, and sends it out at higher pressure. The way it squeezes the gas is what makes different types of compressors.

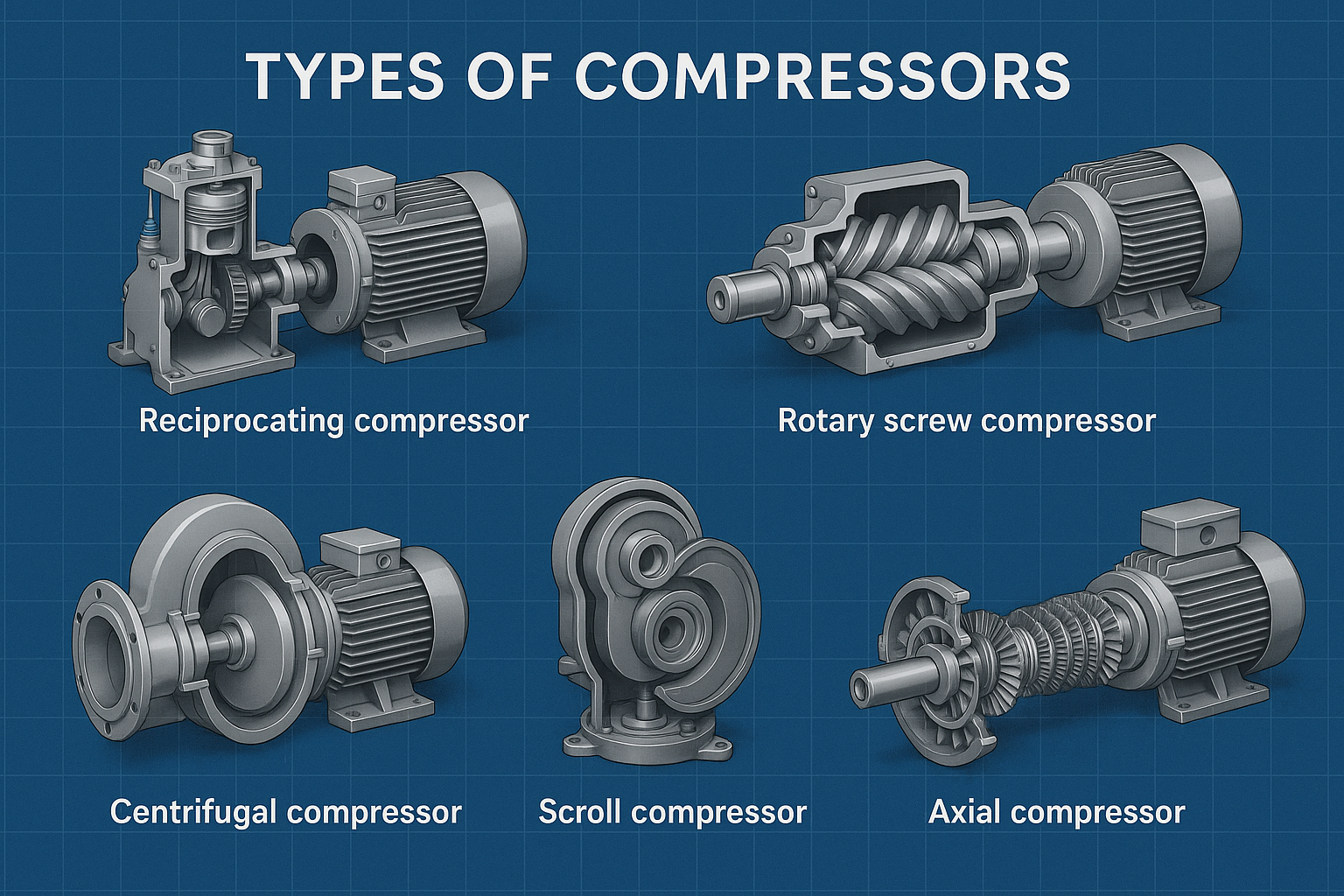

The Two Main Types of Compressors:

All compressors are divided into two broad categories:

- Positive Displacement Compressors – These compressors trap a fixed volume of gas. They then mechanically reduce its volume.

- Dynamic Compressors – These use high-speed rotating elements. They accelerate gas and then turn that velocity into pressure.

Now, let’s dive into each category in more detail.

1. Positive Displacement Compressors:

Positive displacement compressors work by physically trapping a certain amount of air or gas in a chamber. Then, they reduce the volume of that chamber. This makes the pressure go up.

These compressors are great because they give steady pressure and consistent flow. They do this even when their speed changes.

Common Types of Positive Displacement Compressors:

- Reciprocating (Piston) Compressors

- Vane Compressors

- Screw Compressors

- Scroll Compressors

A). Reciprocating (Piston) Compressors:

How it works: A piston moves up and down inside a cylinder. It draws in air when it goes down and compresses it when it goes up.

Advantages:

- Low upfront cost

- High pressure capability

- Simple design and maintenance

Disadvantages:

- Noisy operation

- More moving parts mean more wear and tear

- Limited for continuous heavy-duty use

Best for: Small workshops, garages, and intermittent-duty applications.

B). Vane Compressor:

A vane compressor has a rotor with adjustable vanes. These vanes slide in and out to trap and compress air.

How it works:

- The rotor spins inside an off-center cavity.

- Vanes extend to form compartments.

- As the rotor turns, these compartments shrink. This compresses the air inside.

Advantages:

- Compact size and lightweight

- Smooth, pulse-free airflow

- Easy maintenance

Disadvantages:

- Vanes wear down over time

- Less efficient for large, constant loads

Best for: Light industrial use, automotive service centers, and tire shops.

C). Screw Compressor:

A screw compressor uses two interlocking helical rotors to compress air continuously.

How it works:

- Air enters the compressor housing.

- The rotors trap and push air toward the outlet.

- The space between rotors decreases, raising pressure.

Advantages:

- Continuous, steady air supply

- High efficiency under heavy loads

- Long service life with proper maintenance

Disadvantages:

- Higher purchase cost than piston compressors

- Requires lubrication (unless oil-free)

Best for: Factories, construction sites, and large-scale industrial processes.

D). Scroll Compressor:

A scroll compressor uses two spiral-shaped scrolls. One is fixed, and the other moves. They work together to compress air.

How it works:

- Air enters the outer edge of the scrolls.

- The moving scroll orbits (but doesn’t rotate), pushing air toward the center.

- Volume decreases and pressure increases.

Advantages:

- Very quiet operation

- Few moving parts = less maintenance

- Highly reliable for small to medium loads

Disadvantages:

- Lower capacity compared to screw compressors

- Higher cost for small applications

Best for: Air conditioning, refrigeration, and medical equipment.

2. Dynamic Compressors:

Dynamic compressors do not trap air in a fixed volume. They use high-speed impellers or blades to speed up air. Then, they slow it down in a diffuser to increase pressure.

These compressors are great for large flow rates. They are often used in big places like industrial plants, power generation, and aviation.

Common Types of Dynamic Compressors:

- Centrifugal Compressors

- Axial Compressors

A). Centrifugal Compressors:

A centrifugal compressor uses a rotating impeller to fling air outward at high speed. This process converts velocity into pressure.

How it works:

- Air enters the center of the impeller.

- The impeller spins, pushing air outward.

- The diffuser slows the air, increasing pressure.

Advantages:

- High flow rates

- Fewer moving parts than positive displacement compressors

- Reliable for continuous operation

Disadvantages:

- Less efficient at small loads

- Requires clean, dry air

- Higher initial cost

Best for: HVAC systems, chemical plants, and gas pipelines.

B). Axial Compressors:

An axial compressor works by pushing air through blades. These blades move in a way that keeps the air flowing parallel to the shaft.

How it works:

- Air moves straight along the axis of rotation.

- Each stage slightly increases air pressure.

- Multiple stages create high-pressure output.

Advantages:

- Extremely efficient at high flow rates

- Compact relative to output

- Common in jet engines and power plants

Disadvantages:

- Complex and costly design

- Poor performance at low flow rates

Best for: Jet propulsion, gas turbines, and large-scale industrial power generation.

Compressor vs Pump: What’s the Difference?

It’s easy to confuse compressor vs pump, but they have different functions:

| Feature | Compressor | Pump |

|---|---|---|

| Medium | Gas (usually air) | Liquid or gas |

| Function | Increases pressure by reducing volume | Moves fluid from one place to another |

| Pressure Change | Significant | May be minimal |

| Example | Air compressor in a workshop | Water pump for irrigation |

Key takeaway: A compressor squeezes gas to increase pressure. A pump moves fluids, sometimes with little change in pressure.

How to Choose a Compressor:

When deciding how to choose a compressor, ask yourself:

- What is my application? – Small tools or large industrial machinery?

- What flow rate do I need? – Measured in CFM (cubic feet per minute).

- What pressure do I require? – Measured in PSI (pounds per square inch).

- How often will it run? – Continuous or intermittent duty?

- What space is available? – Portable or stationary?

- What’s my budget? – Consider purchase + operating + maintenance costs.

- Do I need oil-free air? – Important for food, medical, or electronics industries.

Market Trends for Compressors in 2025:

In the World, demand for compressors is being driven by:

- Energy efficiency regulations – More buyers are choosing variable-speed compressors.

- HVAC growth – Rising residential and commercial cooling needs.

- Industrial automation – Increased use in manufacturing and packaging.

- Oil-free technology – Growing demand in food, beverage, and pharmaceutical sectors.

Quick Reference Table:

| Category | Type | Flow Rate | Best Use |

|---|---|---|---|

| Positive Displacement | Reciprocating | Low–Medium | Small workshops |

| Positive Displacement | Vane | Medium | Automotive, light manufacturing |

| Positive Displacement | Screw | High | Factories, heavy industry |

| Positive Displacement | Scroll | Low–Medium | HVAC, refrigeration |

| Dynamic | Centrifugal | High | HVAC plants, pipelines |

| Dynamic | Axial | Very High | Aviation, power plants |

Conclusion:

Learning about types of compressors begins with understanding two main groups: Positive Displacement Compressors and Dynamic Compressors. Models like vane compressors, screw compressors, and scroll compressors are perfect for steady airflow. On the other hand, centrifugal compressors and axial compressors are best for high-volume needs.

Ever thought about the difference between compressor vs pump? Compressors push gas to increase pressure. Pumps, on the other hand, move fluids without always raising pressure.

With this info, you can pick the right compressor for your project. It’s all about matching your needs, budget, and goals.