Piping engineering is key in many industries. This guide will explore the basics of piping systems. We’ll look at their design, how they work, and why they’re important.

It’s important for engineers and industry experts to know the technical details. They also need to understand the rules that guide these systems. In the next sections, we’ll dive into the main parts, new ideas, and challenges in this field.

Understanding the Basics of Piping Engineering:

Piping engineering is key in many industries. It deals with designing and specifying piping systems for fluids and gases. Knowing the basics is vital for those in this field. It involves understanding material properties, flow dynamics, and pressure and thermal calculations.

Fluid mechanics is a cornerstone in piping engineering. It ensures piping systems work efficiently and safely. Knowing about different materials, like steel and plastic, is also important. Each material affects a system’s performance differently.

Designing piping systems involves more than just materials. It also means designing for pressure and temperature changes. Plus, following regulations is a must.

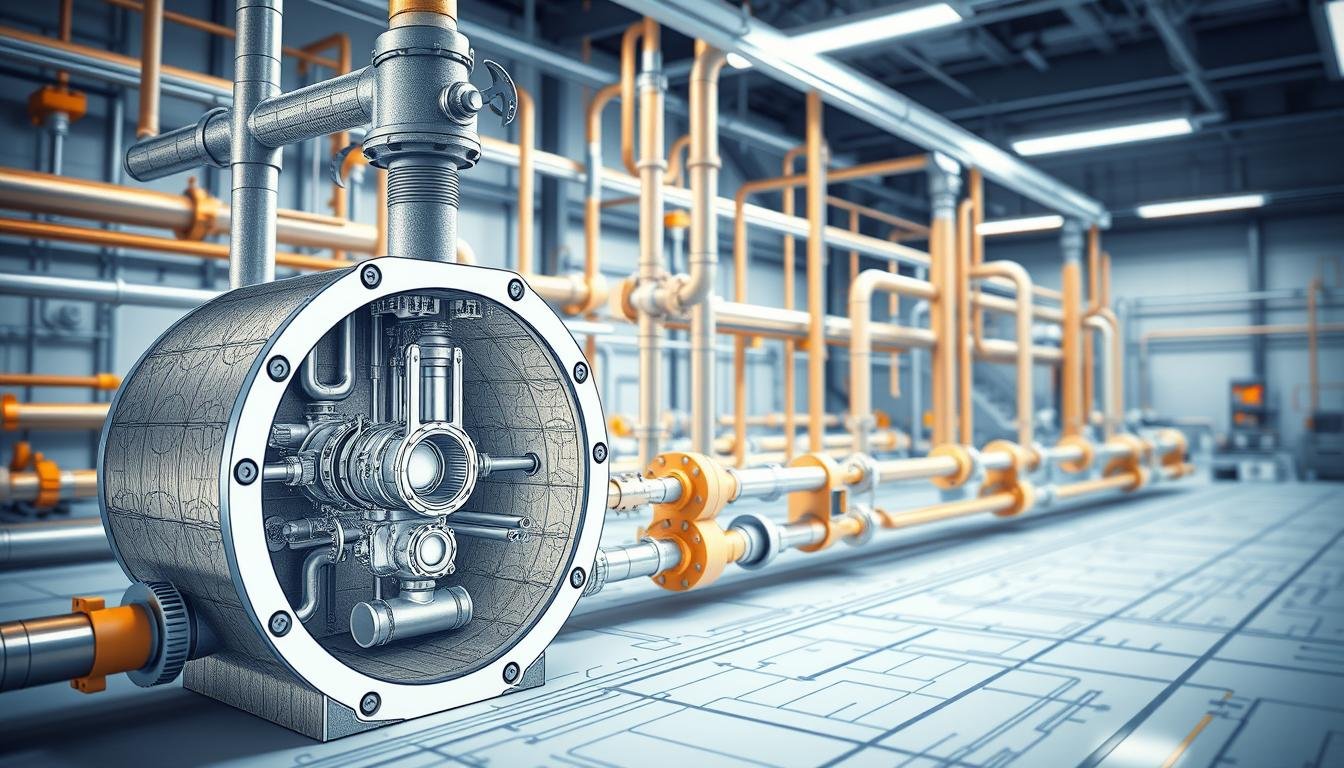

Looking at piping systems as a whole is important. It shows how components like connections, valves, and supports work together. These elements affect flow rates and system reliability. Understanding their role is key to designing and running piping networks well.

Key Components of Piping Systems:

A piping system is vital in many industries. It has many parts that work together for efficiency and safety. The pipes are the main part, carrying fluids from one place to another.

Piping fittings, like elbows and tees, help pipes change direction or size. This makes complex setups possible.

Valves are key for controlling fluid flow and pressure. They help manage liquid flow and prevent problems like backflow or overpressure. Pumps are also important, pushing liquids through the system.

Knowing about these parts shows how important it is to install and maintain them right. This keeps the whole system working well.

Piping Engineering: A Focus on System Design:

In piping engineering, designing systems well is key for safety and efficiency. It requires careful planning, like picking the right pipe sizes and materials. Also, figuring out where to place pipes is important to avoid pressure drops.

My work shows how important it is to follow engineering rules during design. Things like managing heat, vibrations, and support spacing are critical. By doing this and checking the system’s loads, I make sure it works well under different conditions.

The Importance of Piping Standards and Codes:

Following piping standards and codes is key to keeping piping systems safe and reliable. Organizations like the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) create these guidelines. They are essential for engineers designing and building piping systems.

ASME B31.3 is a major standard for process piping. It sets rules for materials, design, making, and testing. This ensures that piping engineering meets high standards. The API 570 Piping Inspection Code also plays a big role. It guides inspections of existing piping to keep systems safe and working well.

Using these codes in my work makes systems more reliable and safe. It also promotes a culture of safety. Understanding the importance of piping standards is vital. It ensures the quality of engineering and keeps people safe on projects.

Common Applications of Piping Engineering:

Piping engineering is used in many fields like oil and gas, chemical processing, and water treatment. Each field has its own needs. For instance, in oil and gas, pipes must handle high pressures. This is key for safe and efficient fluid transport.

In chemical processing, pipes need to resist corrosion and be compatible with materials. This is because harmful substances move through them. Water treatment plants also need special pipes for water flow and filtration. They must meet health and safety standards.

Knowing how piping engineering is used in each field helps me design better. I focus on making piping systems more efficient and reliable for all industries.

Environmental Considerations in Piping Engineering:

In recent years, the environmental impact of piping engineering has become more important. Engineers like me focus on sustainable practices. We design systems that meet regulations to protect ecosystems and communities.

Preventing leaks is key to reducing environmental harm. I use advanced sealing technologies and maintenance to lower leak risks. This protects soil and water. Energy efficiency is also vital. Using new materials and designs saves energy and cuts costs.

Following regulations is essential in my work. Environmental agencies set rules for piping systems. These rules ensure safety and protect our environment. By following these guidelines, I help preserve our natural resources.

Innovations in Piping Engineering Technology:

Exploring advancements in piping engineering, I see big changes. Digital twins and smart sensors are leading the way. They make it possible to monitor systems in real-time, giving us vital data to improve reliability.

With digital solutions, we can also predict problems before they happen. This saves us time and money. It’s a game-changer for the field.

New materials are also making a big impact. They fight corrosion better and make pipes last longer. This means less money spent on replacements and more savings over time.

These advancements are making piping engineering more efficient and effective. It’s an exciting time for the future of this field.

Challenges Faced by Piping Engineers:

Piping engineers face many challenges that can affect project success. One big issue is keeping up with changing laws and safety rules. These changes often bring new problems.

Also, using new technologies adds to the difficulties. It’s a balance between making things work well and being efficient.

Designing piping systems is another big challenge. These systems need coordination from many engineering fields. Good communication and teamwork are key to solving these problems.

Lastly, there’s a shortage of skilled workers in the field. As projects get bigger and more complex, finding the right people is harder. Overcoming these obstacles while keeping safety and quality high is a big part of my job.

The Future of Piping Engineering:

The future of piping engineering is looking bright. We’re moving towards smarter systems. Site automation will be key, allowing for real-time monitoring and management.

Thanks to technology, engineers will use artificial intelligence and the Internet of Things. This will boost operational efficiency.

Predictive maintenance will change how we maintain systems. Instead of fixed schedules, data analytics will predict when maintenance is needed. This approach reduces downtime and extends system life.

Energy efficiency and sustainability are becoming more important. I’m committed to using innovative practices. Future designs must be sustainable and use the latest technologies.

Resources for Aspiring Piping Engineers:

Looking to start a career in piping engineering? You’re in luck because there are many resources available. You can find academic journals and textbooks that cover the basics and advanced topics. These materials help both newbies and experienced professionals improve their skills.

Groups like the American Society of Piping Engineers (ASPE) offer more than just networking. They give you access to the latest industry news. Being part of these organizations helps me keep up with new techniques and trends. They also host seminars and provide ongoing education to enhance my skills.

Getting a degree in mechanical or civil engineering is also key. Schools work with companies to create programs that offer real-world experience. Resources like “Engineering Career Resources” by H. P. M. Calder help me understand what it takes to succeed in piping engineering.