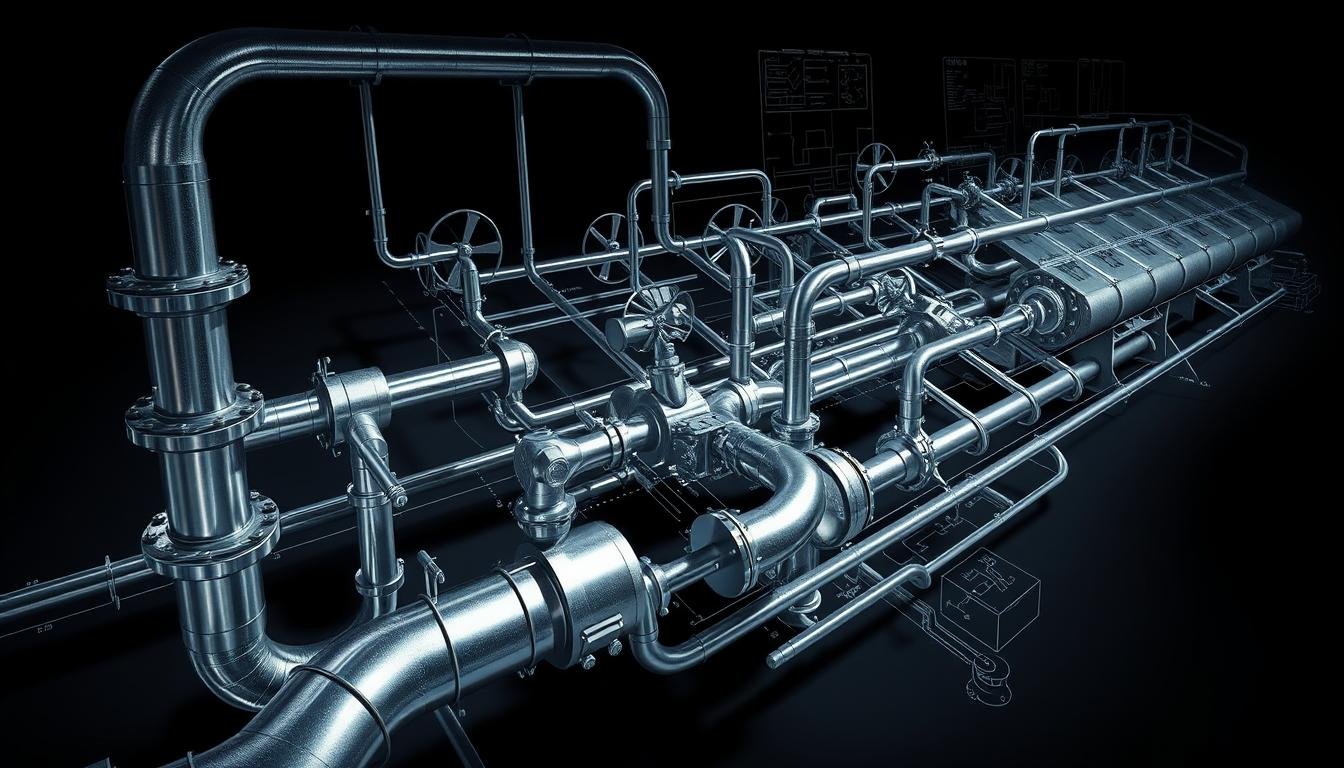

In today’s engineering world, advanced piping design is key. It’s about making piping systems work better and more efficiently. By using the latest techniques, we meet the growing needs of different industries.

Good piping design makes systems reliable and safe. It also boosts efficiency in how things get done. This is important for keeping operations running smoothly.

Understanding the Basics of Piping Design:

The basics of piping design focus on a few key areas. These include choosing the right materials, sizing, and pipe configuration. This ensures fluids move efficiently. Knowing how different fluids behave is key to making systems work better.

When designing pipes, it’s important to consider the specifications. This includes the pressure and temperature limits. I use standards from ASME and ASTM to guide my choices. These guidelines help make sure systems are safe and perform well.

Key Principles of Advanced Piping Design:

Understanding the key principles of advanced piping design is essential. It helps in creating effective systems. The focus is on making design processes more efficient and planning layouts carefully.

This approach leads to lower operational costs and higher productivity. It ensures systems work well and meet standards easily.

By analyzing flow dynamics and optimizing layouts, we manage resources better. This planning also helps in extending the life of piping systems. My studies in fluid mechanics show that well-designed systems perform better and meet regulations more easily.

Successful projects show the value of focusing on efficiency and system integration. They demonstrate the need for an adaptable mindset in the fast-changing world of piping technology.

Innovative Materials Used in Modern Piping Systems:

I’ve been looking into new piping materials and found some exciting changes. High-performance plastics, composites, and metals are leading the way. These materials are made to last longer and resist corrosion, which is great for many uses.

There’s a big push for sustainable materials in the industry. Groups like the Plastic Pipe Institute are pushing for eco-friendly options that don’t sacrifice performance. This shift is changing how we see materials in piping.

High-performance plastics are flexible and light, which is a big plus. Composites offer strength and can handle tough environments. Corrosion-resistant metals are also gaining popularity. Each material has its own benefits and challenges, which designers must consider.

Insights into Piping Design Software and Tools:

Piping design software is key in advanced piping design. CAD tools have changed how we tackle complex designs. Programs like AutoCAD Plant 3D and PDMS (Plant Design Management System) offer great features.

These tools make work easier and help teams work together better. They make designs clearer and easier to change.

Design simulation is vital for checking piping systems before they’re built. It lets me test how fluids flow and systems work under different conditions. This ensures my designs are the best they can be.

Using CAD tools improves accuracy and catches problems early. This saves time and money later on.

Using advanced piping design software makes my work better and faster. Knowing what each tool does helps me pick the right ones for each project. This leads to new ideas and more efficient designs.

Piping Design Best Practices for Efficiency:

Following piping design best practices can make systems work better and save money. It’s important to have good procurement processes. This means getting quality materials at good prices to make the systems last longer and stay within budget.

Doing a lifecycle analysis is key to knowing how a system will perform over time. It helps me see the full cost of owning a system, not just the initial setup. This way, I can plan for repairs and maintenance, saving money in the long run.

Using industry standards and expert advice helps me make better choices. It leads to better use of resources and more efficient systems. My goal is to design piping systems that are both practical and sustainable.

Understanding Fluid Dynamics in Piping Design:

In my work on piping design, I always look at fluid dynamics. It’s key to how well a system works. Knowing how fluids flow is essential, as it affects their movement through different pipes and setups.

Fluid dynamics plays a big role in several important areas of piping systems. For example, a big pressure drop can make a system less efficient. It can also raise energy costs and cause problems. By using Bernoulli’s equation, I can figure out how changes in speed and height affect pressure. This helps me pick the right pipe sizes and layouts.

In real life, these principles are very important. For example, in chemical plants, where controlling fluids is critical, good piping design based on fluid dynamics makes a big difference. It reduces pressure drops, leading to better flow and lower costs. Every project is a chance to use these important ideas to improve system design.

Piping Design: Application in Different Industries:

Exploring piping design shows how different industries use advanced methods to meet their needs. The chemical industry faces strict rules and works with dangerous materials. It needs strong and dependable piping systems.

Engineers must design these systems to resist corrosion and handle temperature changes. This ensures safety and follows the rules.

In the oil and gas field, piping design is very complex. Systems must carry volatile substances safely from offshore to refineries. They must also handle harsh weather conditions.

Designs need to be durable and leak-proof. This is key for the industry’s success.

The food processing industry also has its own set of challenges. Keeping things clean is a top priority. This affects the materials and design standards used.

Piping designs must make cleaning and maintenance easy. This helps prevent contamination. Knowing these needs helps create better piping solutions that meet industry standards.

Challenges and Solutions in Advanced Piping Design:

Advanced piping design comes with many challenges. These can affect the success of a project. One big issue is keeping up with safety standards, which are strict in some industries.

Project management is key to solving these problems. It’s important to use effective strategies to manage projects well. This includes good communication among team members.

Using advanced technologies can also help. These tools allow for better tracking and management of projects. They help teams stay on track and meet safety standards.

The Future of Piping Design Technology:

Looking ahead, piping design technology is set for a big change. The digital transformation is changing how we design and manage piping systems. New tech like the Internet of Things (IoT) and Artificial Intelligence (AI) are key to smart piping systems.

These changes will make systems more efficient, cut costs, and boost safety. It’s a big step forward for many industries.

Real-time data analytics will play a big role in piping design soon. IoT devices will send constant updates and monitor the environment. This data will help make better design choices.

It will also help predict when maintenance is needed. This means systems will run better and last longer. It’s a big change in how we take care of piping systems.

AI will also become more important in piping design. It will help solve complex problems and make design faster. With AI, engineers can test designs quickly and see how they might work.

In the end, combining these technologies will lead to better piping systems. They will be more sustainable, strong, and efficient. They will meet the needs of industries as they grow and change.