In this article, I explore the key aspects of ball and roller bearings. We’ll look at their design, how they work, and what happens when they fail. These bearings are vital in many industries, making machines run smoothly and efficiently.

Knowing how bearings are designed helps us see how they work best in different situations. The way they operate is also key to keeping machines running long. And, understanding how to analyze failures helps avoid expensive downtime and boosts productivity.

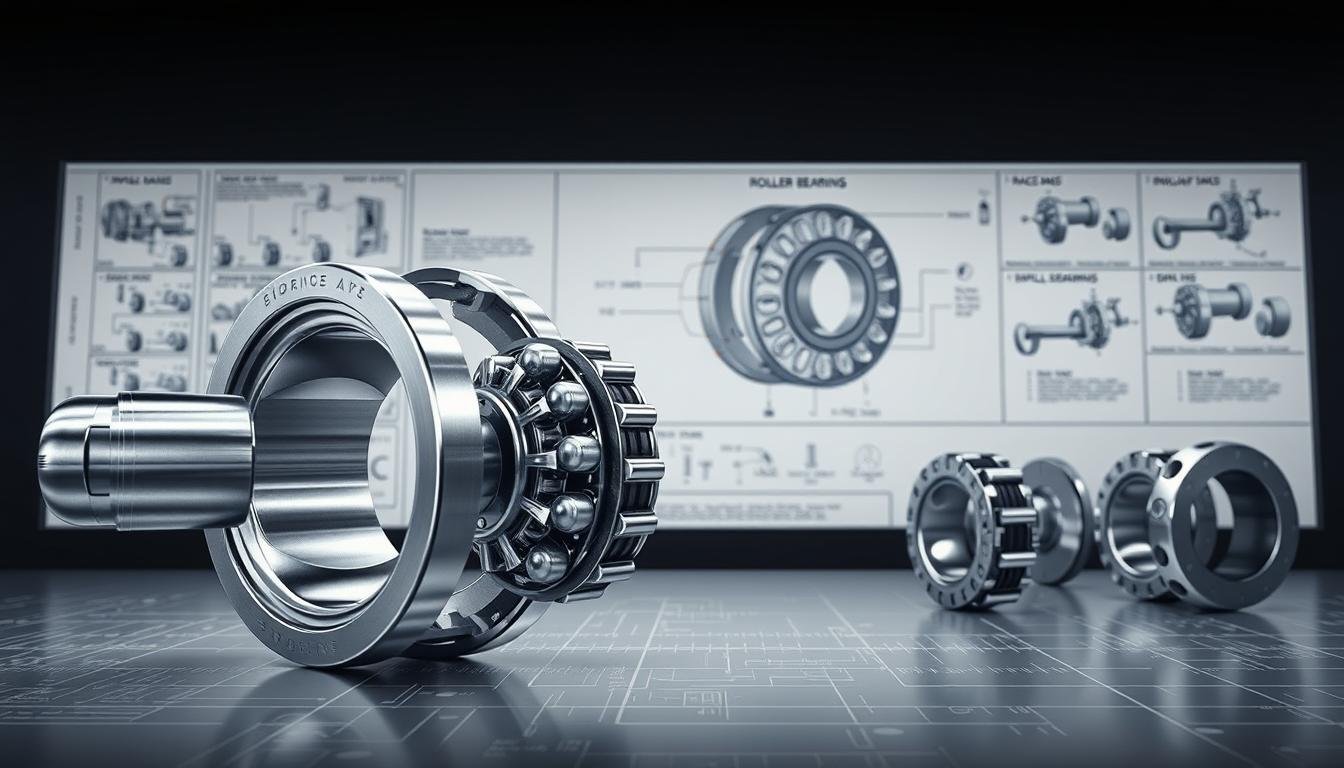

Introduction to Ball and Roller Bearings:

In this section, I will explore the basics of ball and roller bearings. We’ll look at their structure and how they work. These components are key in mechanical systems, making movement smooth and reducing friction.

Bearings are essential in machinery, supporting rotating shafts and improving performance. They are used in many industries, from cars to airplanes. Knowing about these components is important for designing or maintaining machinery.

Understanding the Design Essentials:

In my study of ball and roller bearings, I focus on key design elements. These elements are vital for performance. They help these parts handle loads and last longer.

The choice of materials is also critical. Options like steel, ceramic, and polymers have their own benefits and drawbacks. These choices affect how long the bearings last and how well they work.

The design of these bearings is carefully planned. It ensures that loads are distributed evenly. This affects their lifespan and how they perform under stress.

By understanding these design principles, I learn how different setups and materials improve ball and roller bearings. This knowledge helps them work better in many situations.

How Ball and Roller Bearings Operate:

It’s important to understand how ball and roller bearings work. They help machines move smoothly and handle loads well. Their shape, whether round or cylindrical, makes them efficient by reducing friction.

The way bearings work involves two types of friction. Static friction happens when the bearing is not moving. Dynamic friction occurs when it’s in motion. Good bearings reduce these frictions, making them more efficient and cooler to run. This helps them last longer, which is key in many uses.

Bearings can handle loads in different ways. Ball bearings are great for radial loads, while roller bearings work best with axial loads. Choosing the right type of bearing is key to making machines work better and last longer.

Types of Ball Bearings:

Knowing the different ball bearing types is key to picking the right one for your needs. Deep groove ball bearings are versatile. They handle loads in both directions and have low friction. They’re used in electric motors, cars, and machines.

Angular contact ball bearings are another important type. Their races are at an angle, making them precise for combined loads. They’re great for high-speed uses like spindles and robotics.

Self-aligning ball bearings also stand out. They have two rows of balls and can handle slight misalignment. This makes them perfect for machinery that’s not always perfectly aligned, like in farming.

Choosing the right ball bearing is critical for machine performance and life. By knowing the differences between deep groove, angular contact, and self-aligning bearings, I can make better choices. This improves efficiency in my projects.

Types of Roller Bearings:

Roller bearings come in different types, each with its own strengths. Cylindrical roller bearings handle high radial loads well. They are perfect for heavy machinery and industrial settings. Their design reduces friction, leading to better performance and longer life.

Spherical roller bearings stand out for their ability to work with misalignment. They can handle angular misalignment without losing load-bearing efficiency. This makes them great for applications where the shaft might move. They can handle both radial and axial loads, making them versatile.

Tapered roller bearings are good at supporting combined loads. Their angled design helps distribute forces effectively. This makes them excellent for use in cars and heavy-duty machinery. Knowing about these types helps me choose the right bearings for different mechanical needs, improving system performance.

Importance of lubrication in Ball and Roller Bearings:

Knowing how important bearing lubrication is helps keep ball and roller bearings running well for a long time. Using the right lubrication, like grease or oil, cuts down on friction. This reduces wear and prevents overheating.

Choosing the right lubricant is key to keeping bearings running smoothly. Grease acts as a barrier against dirt, while oil helps with heat and flow. It’s important to think about speed, load, and where the bearing is used to pick the best lubricant.

Putting a focus on lubrication means better equipment performance and lower maintenance costs. Using the right lubrication methods makes machinery more reliable.

Common Failure Modes in Bearings:

Understanding common failure modes in ball and roller bearings is key. Fatigue failure and wear failure are the main issues. Fatigue failure happens when repeated stress weakens the material, causing cracks and failure. It’s hard to spot early.

Wear failure comes from materials rubbing against each other, creating friction. This friction wears down the bearing surfaces over time. It can also be worsened by poor lubrication, showing how important regular maintenance is.

Corrosion is another big problem, mainly in wet or chemical-rich environments. It can make the bearing surfaces weak, leading to early failure. Misalignment also causes stress, leading to uneven wear and fatigue. Knowing these failure modes helps in taking action and maintaining bearings properly.

Failure Symptoms to Monitor:

It’s key to watch for signs of bearing failure to keep machinery running well. Unusual vibrations are often the first sign of trouble. I look for any big changes in vibration patterns, as they can mean a problem is coming.

By using vibration analysis, I can catch issues early. This helps avoid big breakdowns.

I also listen for odd noises. Sounds like grinding, squeaking, or rattling can mean the bearings are wearing out. Doing a detailed noise analysis helps find the source of these sounds. This leads to quick action.

Keeping the operating temperature right is also important. Unexpected high temperatures might mean there’s a lubrication problem or too much friction. Using both vibration and noise analysis gives me important info. This helps me take steps to prevent big failures.

Impact of Operating Conditions:

When I looked into ball and roller bearings, I saw how operating conditions affect them. Temperature is a big factor. High temperatures can make bearings wear out faster and reduce how well they lubricate. On the other hand, very cold temperatures can make lubricants thicker, which affects how smoothly they work.

Load effects are also very important. Bearings handle different loads, and knowing how these loads affect them is key. Too much load can cause them to bend or break. Not enough load can lead to slipping and poor performance. The mix of temperature and load creates complex challenges that need careful study.

Environmental factors like humidity and contaminants also matter a lot. They can cause corrosion and contamination, making things harder for bearings. Understanding these factors helps us make bearings work better in different situations. This makes them more reliable and efficient.

Diagnosis of Bearing Failures:

Understanding how bearings fail is key to keeping machines running well. I use a detailed approach that includes finding the root cause and using different diagnostic methods. Spotting the real problem behind a bearing failure is vital to avoid it happening again.

Advanced diagnostic tools are a big help in this process. They show how bearings are working and if there are any problems. I make sure to do thorough checks to find signs of wear and understand what led to the failure.

Root cause analysis helps us dig deeper into why failures happen. It looks into each failure to find out what really caused it. This way, we can make better choices about how to maintain and run our machines.

Preventive Maintenance Strategies:

Effective preventive maintenance is key to keeping ball and roller bearings running well for a long time. Regular checks are a must. They help spot problems early and prevent big issues later.

Lubrication is also vital for bearing health. A regular lubrication schedule keeps things running smoothly. It reduces wear and tear, making bearings last longer. Choosing the right lubricant and using it as directed is critical.

Watching the environment around the bearings is important too. I monitor things like temperature, humidity, and dirt levels. These can really affect how well bearings work. By keeping an eye on these factors, I can adjust my maintenance plans to fit the bearings’ needs.

The Future of Bearing Technology:

The world of bearing technology is on the verge of a big change. New smart bearings are coming, changing how ball and roller bearings work. These smart bearings use sensors and connect to the internet for real-time checks.

This means bearings can last longer and work better in many places. It’s a big step forward for reliability and performance.

New materials are also on the way, making bearings lighter and stronger. This meets the needs of today’s fast-paced machines. Advances in materials science and tribology are key here. They help reduce friction and wear.

Smart bearings will be key in many fields, like aerospace and renewable energy. These areas need high precision and reliability. It’s exciting to see how these technologies will shape the future.

In short, the future of bearing technology looks bright. We can expect better efficiency, less maintenance, and more capabilities. Staying updated on these changes is vital for anyone in the bearing world.

Case Studies on Bearing Failures:

Looking at real-world bearing failure case studies, I see how important it is to understand these failures well. For instance, a major automaker faced a big problem when their bearings failed because of bad lubrication. This caused a lot of downtime. It shows how key proper lubrication is in making bearings last longer and why we need to watch our practices closely.

In another case, a manufacturing plant had roller bearings fail early. It turned out that the bearings were not installed correctly. This teaches us how important it is to follow the right steps and check for alignment during installation. If we don’t, it can lead to big problems and costs.

These case studies show us not just what went wrong but also how we can do better. By learning from these examples, I can make my operations and maintenance better. Knowing the details of bearing failures helps us avoid problems and makes our systems more reliable and efficient.