In the world of industrial machinery, the importance of bearing design is huge. Bearings help reduce friction and wear, which boosts machinery efficiency. As I dive into the details of bearing technology, it’s clear that good bearing design is key to top performance.

By learning how to improve bearing design, I can make sure machinery works its best. This also helps extend its life.

Understanding the Role of Bearings in Machinery:

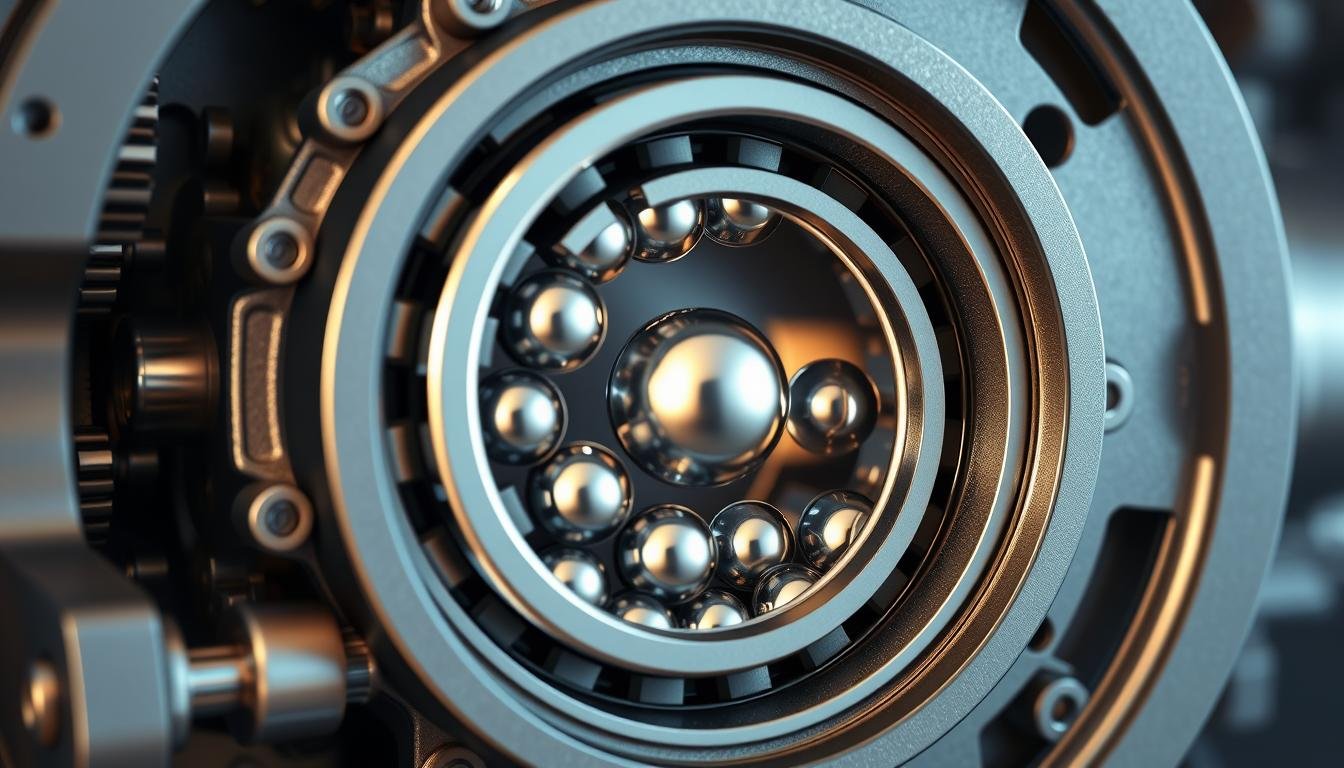

Bearings are key to a machine’s performance and lifespan. They support rotating shafts, making them work well under different loads. This support helps distribute loads evenly across the machine.

Bearings also make movement smooth, which reduces friction. Less friction means less heat and wear, helping machines last longer. The design and alignment of bearings are critical for a machine’s efficiency and function.

Knowing how bearings work helps choose the right ones for each job. This knowledge makes machines more reliable and durable. It also cuts down on maintenance costs and keeps machines running.

Key Principles of Bearing Design:

Understanding bearing design is key for top machine performance. Load ratings show how much force a bearing can handle. This affects how long it lasts and how well it works under different conditions.

Choosing the right bearing based on load ratings is important. It helps avoid early wear and failure.

The shape of a bearing is also vital. Different shapes are best for different uses. They affect things like friction and how well the bearing fits in place.

Looking at a bearing’s shape can help find the best design for each job.

Material choice is also critical in bearing design. The right materials can handle things like humidity or changing temperatures. This makes the bearing work better.

It’s also important to match the bearing with the job it’s doing. This includes things like speed and how much load it will carry. Following these principles can make machines more reliable and efficient.

Types of Bearings Used in Industrial Applications:

Exploring industrial applications, I see that knowing about bearings is key. Ball bearings are vital, used in many machines. They handle both radial and axial loads well, making them versatile. Their design also reduces friction, improving efficiency.

Roller bearings are another important type. They’re great for supporting heavy loads. Their cylindrical shape spreads weight evenly, making them durable and long-lasting. This is why they’re often used in heavy machinery.

Thrust bearings are specialized for axial loads. They’re essential in cars and industrial machines. They help manage force in one direction. Knowing about these bearings helps make better choices in industry, ensuring things work well and last long.

Bearing Materials and Their Properties:

In the world of bearing design, the choice of materials is key. Steel and ceramic bearings are top picks because of their special properties. Steel is strong and lasts long, making it great for tough jobs. It can handle heavy loads without breaking down.

Ceramic bearings, though, are better at fighting off corrosion and are lighter. They’re perfect for places where weight and chemical exposure matter. Their high hardness and low friction are great for fast-moving parts where heat and wear are big issues.

Cost is also important when picking bearing materials. Ceramic bearings might perform better, but they cost more. This can limit their use in projects with tight budgets. Knowing about material properties helps figure out performance and cost over time. This way, I can make smart choices about bearing materials, balancing what they can do with what they cost.

Manufacturing Processes for Bearings:

The way bearings are made is key to their quality and how well they work. I begin with forging, which shapes raw materials under high pressure. This method gives bearings the strength and durability they need.

Then, I use machining to make the forged parts precise. Precision engineering is vital here. It ensures the bearings fit perfectly in the machinery they power.

Heat treatment comes after machining. It makes the materials harder and more resistant to wear. This step is important for the bearing’s lifespan. Throughout the process, quality checks are strict. ISO standards help make sure every bearing is reliable and performs well.

Design Considerations for Optimal Bearing Performance:

Creating the best bearing design requires careful thought on several key points. One major factor is lubrication. It helps reduce friction and wear, making bearings last longer. Different lubricants, like grease or oil, are chosen based on the application to work well under various loads.

Keeping the temperature right is also essential. Bearings work best within a certain temperature range. Too much heat can shorten their life. Using cooling methods or materials that handle high temperatures is important. Adding temperature sensors helps make adjustments as needed to keep things running smoothly.

How bearings are aligned is also critical. If they’re not aligned right, they can wear out faster. Using precise alignment techniques ensures bearings handle dynamic loads well. This also reduces stress on other parts.

Common Bearing Design Challenges:

Understanding common bearing design challenges is key to ensuring machinery works well. Wear is a big problem that can cause bearings to fail early. This wear comes from bad lubrication, material fatigue, and wrong alignment.

When we face these issues, finding solutions is critical. By spotting wear patterns and knowing their causes, we can fix problems. For instance, if a bearing wears too much, checking lubrication and alignment can help.

Fixing these challenges helps avoid risks and makes machinery work better.

Innovations in Bearing Design Technology:

The world of bearing design is changing fast. Bearing innovation is key to making machines work better. Smart bearings lead this change, with sensors that track performance in real time. This lets engineers spot problems early, making repairs quicker and reducing downtime.

New materials are also changing how bearings are made. Advanced polymers and composites make bearings last longer by resisting wear and corrosion. Coatings that reduce friction and handle heat are another innovation, helping bearings perform well in tough conditions.

Design trends are moving towards being more eco-friendly and efficient. Makers are focusing on making bearings lighter but just as strong. This blend of new designs and materials boosts performance in many areas.

The Importance of Bearing Maintenance:

In my experience, keeping bearings well-maintained is key to extending machinery life. Ignoring this can cause early failure, expensive downtime, and lower efficiency. Regular checks help me spot wear and tear early, avoiding bigger issues later.

Lubrication is also vital for bearings. It reduces friction and heat, which can damage bearings. I follow the manufacturer’s advice on when and how to lubricate for the best results.

Over the years, I’ve seen how good maintenance extends bearing life. A routine that includes regular checks, timely lubrication, and watching for wear signs greatly improves machinery reliability. By focusing on bearing care, I keep my equipment running smoothly.

Bearing Analysis Techniques in Engineering:

In my engineering journey, I’ve seen how important bearing analysis is. Techniques like finite element analysis (FEA) help us understand how bearings work. It lets us see how they handle different conditions.

FEA lets us test different scenarios. This way, we can check stress and shape changes in bearings. It’s a key tool for engineers.

Vibration analysis is another tool I use. It lets me check bearings in real-time. I can spot problems like wear or failure.

By looking at vibrations, I learn more about bearings. This helps us plan better maintenance. It makes our projects more reliable and efficient.

Impact of Bearing Design on Machinery Efficiency:

The design of bearings has a big impact on how well machinery works. Choosing the right bearings can make a big difference. It affects how much energy a machine uses and how hot it gets.

Good bearings reduce friction, which saves energy and makes machines last longer. This is important for keeping machines running smoothly.

For example, using top-notch bearings can make machines run cooler. This makes them more efficient. Studies show that machines with the best bearings use less energy.

This shows that smart bearing design is key. It helps machines work better and need less maintenance. This means machines can do more work without breaking down.

Future Trends in Bearing Design:

Sustainability is key in the future of bearing design. The industry is moving towards using biodegradable materials and energy-saving designs. These changes will reduce environmental harm and improve machine performance.

Digitalization is also a big trend. The Internet of Things (IoT) is being added to bearings for real-time monitoring. This leads to better machine uptime and efficiency. It’s changing how we maintain machines, making them more reliable and efficient.

The mix of sustainability and digital solutions will change the industry. These trends show that bearing design is set for a big change. It will focus on being green while also being efficient.