Exploring the effects of misalignment shows how it can harm machinery and productivity. In many fields, misalignment is a hidden problem that only shows its impact when it’s too late. It can cause a lot of downtime or expensive fixes.

Knowing the many ways misalignment affects things is key. It shows why we need to manage it well. In this piece, I’ll look at how misalignment can slow things down, raise maintenance costs, and lead to waste. All these can hurt a company’s profits.

Understanding Misalignment and Its Importance:

Misalignment means machine parts are not set up right. This can happen because of wear, mistakes in setting up, or stress from use. Knowing how important alignment is is key. It affects how well machines work and how efficient operations are.

Getting alignment right helps machines last longer, saves energy, and cuts down on breakdowns. In my experience, keeping machines aligned is vital in many fields. It leads to better work flow and more productivity. By understanding the importance of alignment, we can take steps to keep machines running smoothly and protect our work.

Common Causes of Misalignment:

Misalignment can come from many sources, leading to less efficient equipment and possible damage. Mechanical wear is a big cause. Parts can wear down over time, causing misalignment that hurts how well the machinery works. Regular checks are key to spotting these changes.

Thermal expansion is another big factor. When machines run, temperature changes can make parts expand and contract. This is common in places with changing temperatures, affecting how well the machine works. Knowing how temperature affects machines helps predict alignment problems.

Installation mistakes also play a role. I’ve seen how wrong setup can lead to misalignment right from the start. It’s critical to align each part correctly when setting up. Also, things like vibrations from other machines or shocks can make alignment worse. These issues often go unnoticed until they cause big problems.

It’s important to keep an eye on these causes of misalignment. Regular checks can stop problems from getting worse. By tackling these issues early, I can keep the equipment running smoothly and for longer.

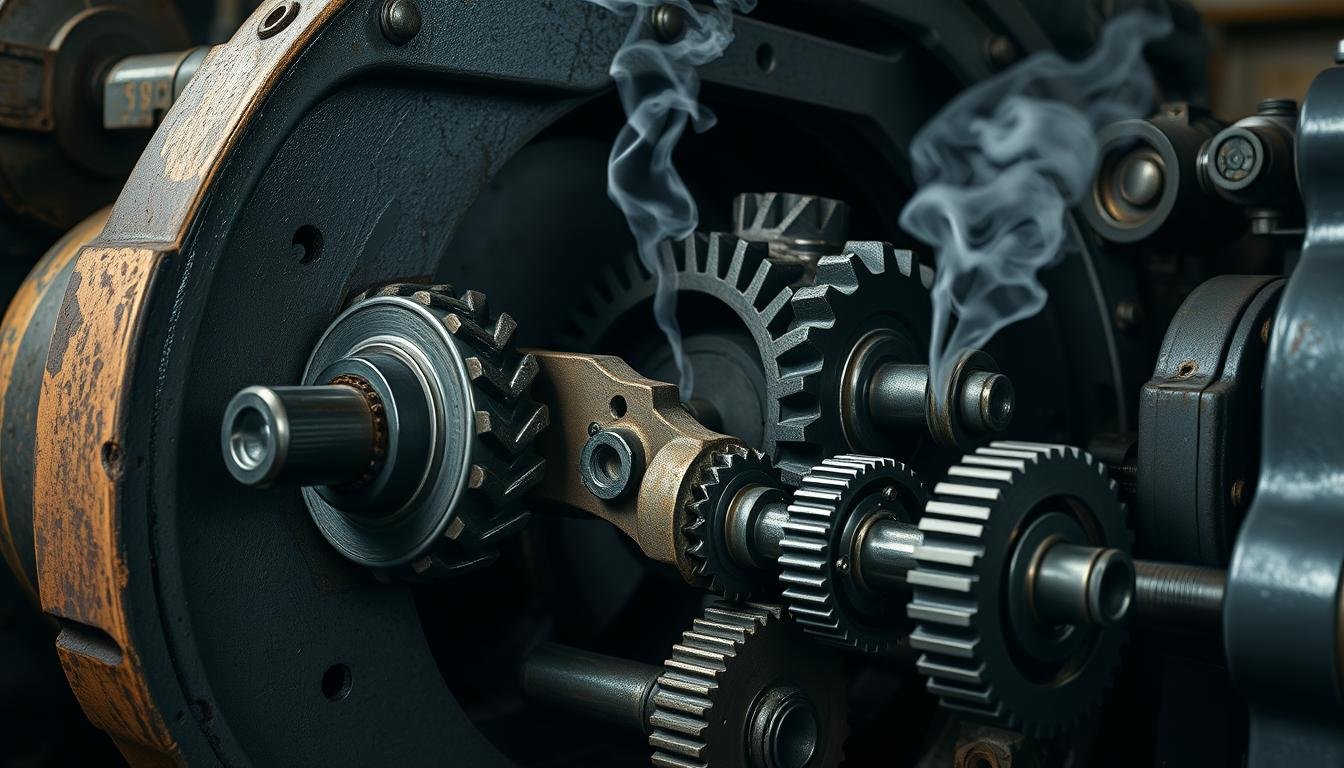

Effects of Misalignment on Machinery Performance:

Misalignment has big effects on how well machinery works. It causes more friction and uses more energy. This makes parts wear out faster and can lead to equipment breaking down.

When equipment fails, it stops working without warning. This can hurt productivity and lower profits. It’s a big problem for businesses.

Also, misaligned machinery makes a lot of noise and shakes a lot. This can damage other machines and is dangerous for people nearby.

To fix these problems, it’s important to keep machinery in good shape. Regular checks can make sure it runs well. This cuts down on downtime and boosts productivity.

The Connection Between Misalignment and Productivity:

Misalignment and productivity in industrial settings are closely linked. When machinery is not aligned properly, it’s clear that productivity drops. This misalignment slows down production and lowers the quality of what’s made.

In manufacturing, even a small misalignment can cause big problems. It leads to inefficiencies that add up over time. This hurts how well equipment works and increases maintenance costs.

By focusing on alignment checks and maintenance, we can fix these problems. Good alignment practices boost productivity and make operations smoother. This means faster production and better use of resources. Knowing this helps me push for better alignment and productivity in my team.

Misalignment and Maintenance Costs:

Misalignment is a big factor in how much maintenance costs. When parts aren’t aligned right, they wear out faster. This means more repairs and replacements are needed, adding to the expenses.

Seeing machinery that’s not running well can be costly. Regular checks and maintenance can help avoid these high costs. By fixing alignment problems early, we can save money and keep operations running smoothly.

Identifying Signs of Misalignment in Machinery:

Spotting misalignment in machinery is key to keeping it running smoothly and avoiding expensive fixes. Look out for signs like unusual vibrations, loud noises, heat, and uneven wear on parts. These signs can point to bigger problems if not fixed.

Tools like vibration analysis and laser alignment help me find these issues fast. I also do visual checks to get a better look at the machinery’s state. Using these methods together lets me catch problems early. This helps prevent big breakdowns and makes equipment last longer.

Correcting Misalignment: Effective Techniques:

Fixing misalignment is key to keeping machinery running well. I use different alignment methods to boost equipment reliability and efficiency. For example, shimming is a manual method that works great for small tweaks. Alignment tools like dial indicators help me check if the adjustments are right.

Laser alignment is another advanced method that’s very accurate. It’s popular in industrial settings. Using these tools ensures machinery is aligned perfectly, reducing wear and tear. These methods not only fix misalignment but also promote regular maintenance.

It’s important to keep learning about alignment techniques and new technologies. This dedication helps machines last longer and work better over time.

The Benefits of Regular Alignment Checks:

Regular alignment checks are key to better machinery reliability. They help cut down on maintenance costs. This approach fixes problems early, saving money in the long run.

Having a routine for these checks promotes a culture of care. It leads to longer-lasting equipment and boosts productivity. This way, equipment works better and for longer, reducing the chance of sudden failures.

Adding these practices to maintenance plans improves operations over time. Reliable machinery boosts everyone’s confidence in its performance. Regular checks are essential for keeping things running smoothly and protecting productivity.

Case Studies: The Impact of Misalignment:

Looking at real-world examples shows how misalignment affects different areas. In manufacturing, for instance, it causes delays and makes machines less efficient. A big example is an automotive assembly line where misaligned conveyor systems cut down production a lot.

In the energy field, misalignment can be very dangerous and costly. A wind farm had turbines breaking down often because they were not aligned right. This cost the company a lot of money, showing how big the problems can get.

These stories are key to understanding how misalignment impacts various industries. They offer lessons on how to fix these issues and improve performance. By studying these examples, I see why it’s so important to fix misalignment in any operation.

Future Trends in Alignment Technology:

The field of alignment technology is growing fast, with exciting trends on the horizon. Predictive maintenance systems are leading the way. They use data analytics to spot problems before they start, helping machines run smoothly.

Advanced diagnostics are also key. Tools with top-notch sensors can catch even small alignment issues. This gives us accurate data for quick fixes. These trends are vital for keeping machinery reliable and efficient.

Artificial intelligence is changing the game in alignment. AI systems learn from data to make the alignment process quicker and more accurate. As we see these advancements, it’s clear we need to stay up-to-date to use them to our advantage.