Pump reliability is key in industrial settings. It affects how well things run and how much gets done. I know how important it is to have pumps that work well.

Good pumps mean less downtime and better service in making things. By keeping pumps in top shape, I protect my equipment and save money too.

Understanding Pump Reliability:

Pump reliability means a pump works well over time without breaking down. This is key in industries, as it affects how much work gets done and costs. Many things can make a pump reliable or not, like its design, materials, and where it’s used.

Knowing how a pump works is key to keeping it running smoothly. For example, a pump might do great in certain conditions but struggle with others. Knowing this helps pick the best equipment and make smart choices about upkeep and updates.

Common Causes of Pump Failure:

Understanding why pumps fail is key to keeping them running smoothly. Mechanical failures are a big problem, caused by wear and tear. Parts like bearings, impellers, and seals can wear out, leading to problems.

Cavitation is another major cause of pump failure. It happens when vapor bubbles form and then collapse, damaging the impeller. Spotting cavitation early is important to keep the pump in good shape. Also, mistakes in how the pump is used, like wrong speed or flow rates, can cause failure.

Installing a pump wrong can also lead to trouble. If it’s not set up right or the pipes are bad, the pump might fail. I’ve seen many cases where not knowing how to install properly led to early failures. And, ignoring maintenance can also cause pumps to fail. Regular checks and maintenance can stop many problems before they start.

Regular Maintenance Strategies:

Effective pump maintenance strategies are key to long-term reliability and efficiency. It’s important to set up routine maintenance schedules for each pump. Regular inspections can catch problems early, preventing bigger issues.

Using advanced techniques like vibration analysis and thermal imaging helps a lot. These methods give valuable insights into pump health. They help spot anomalies early, guiding decisions on adjustments or repairs. The American Society of Mechanical Engineers says following maintenance schedules cuts down on unexpected failures.

Monitor Pump Performance Metrics:

Effective pump monitoring needs a deep understanding of key performance metrics. I look at flow rate, pressure, and power consumption. These metrics show how well pumps work and how reliable they are.

By analyzing these metrics, I can spot problems early. This helps prevent bigger issues later on.

I use advanced tools and software to track these KPIs for pumps. This helps me see trends and oddities. It supports keeping pumps in top shape, reducing downtime and extending their life.

The Role of Quality Equipment in Reliability:

Investing in quality pumps greatly affects pump reliability. I’ve seen how using equipment from trusted brands improves performance and extends lifespan. High-quality materials and designs lead to fewer breakdowns, saving on maintenance costs.

Following industry standards like ISO is key. It ensures pumps meet strict requirements for performance under different conditions.

Not all pumps are the same, as my experience shows. Some brands offer warranties and certifications, showing their dedication to quality. This gives me confidence in my investment. By focusing on quality, I keep my systems running smoothly, reducing downtime and boosting productivity.

Choosing the Right Pump for Your Application:

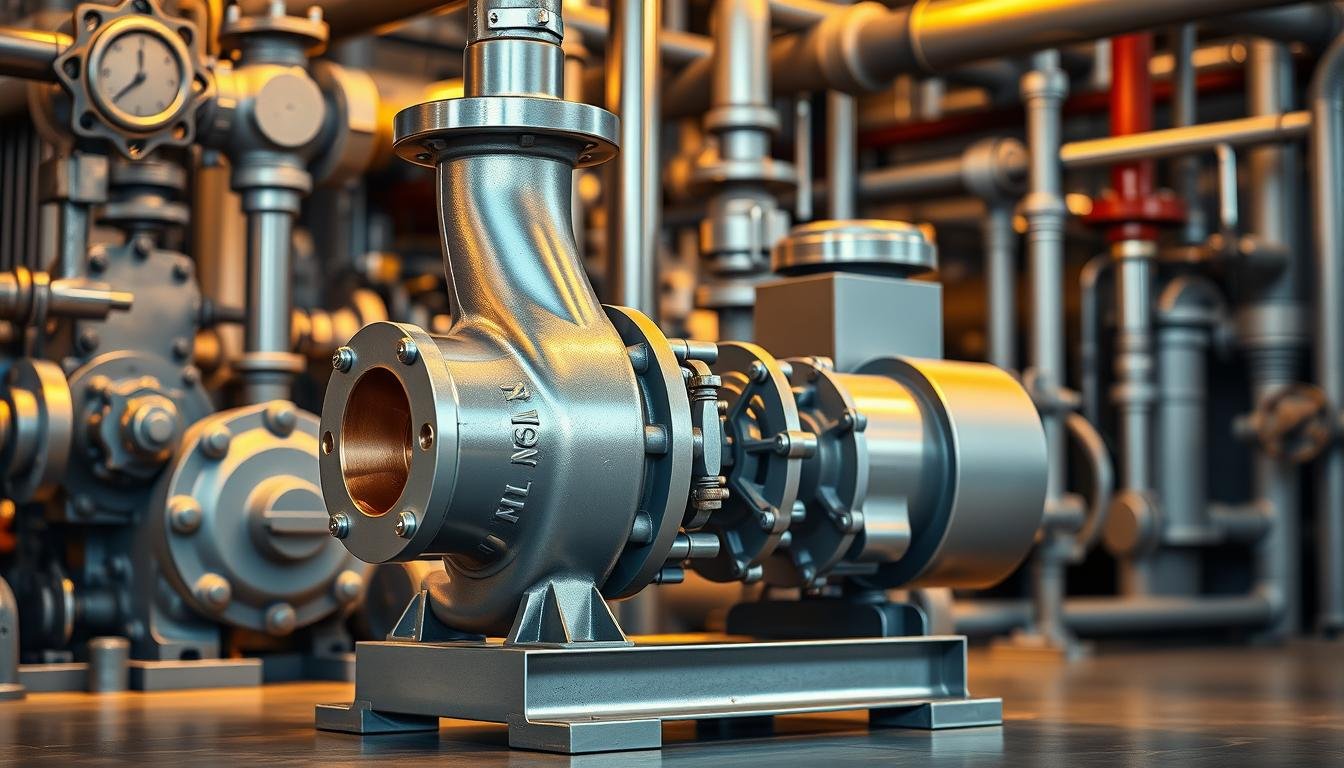

When picking a pump, knowing what your application needs is key. Different pumps are better for different jobs. For example, centrifugal pumps are great for high flow rates, like in water supply and chemical processing.

Positive displacement pumps are better for precise flow control. They’re perfect for tasks like lubrication and metering. This shows how important it is to choose the right pump for your needs.

Submersible pumps are made for underwater use. They’re ideal for dewatering or sewage work. Each pump type has its own strengths and weaknesses. So, it’s vital to think about your process needs before choosing.

By picking the right pump for your application, you can get the best performance and durability. This careful selection ensures your pump works well for a long time.

Implementing Preventive Measures:

To make pumps more reliable, I focus on preventive measures. These steps are key for keeping pumps in good shape. Regular checks help me spot problems before they get worse.

Adding predictive maintenance to our plan helps a lot. It lets us catch issues early and fix them fast. This saves money and keeps the pumps running smoothly. It’s also important to train the team to spot problems. This way, everyone knows what to look for and we follow the best practices.

Alternate Materials for Enhancing Longevity:

In my search for the best materials for pumps, I’ve learned that the choice is key. The pump’s environment helps decide the best materials for top performance. Advanced composites and corrosion-resistant alloys stand out for their durability and low maintenance.

Working in harsh environments means picking the right materials is more than just a choice. It’s a necessity. These materials protect the pump’s parts from damage, leading to a longer life. This approach cuts down on downtime and saves money in the long run.

Using top-notch materials for pumps helps avoid system failures. Knowing the unique qualities of these materials helps make better choices. This ensures the pumping system is both durable and reliable.

Automating Pump Monitoring Systems:

In today’s fast-paced world, automated pump monitoring systems have changed how we manage pumps. They use IoT to collect data in real-time. This lets me check how pumps are doing all the time.

These systems give us key insights into how pumps are working. They help spot problems early, before they cause big issues.

Using pump automation makes things run smoother and more efficiently. It cuts down on mistakes and makes sure we act fast. This means we can fix problems before they get worse.

With these new tools, we can plan maintenance better. This leads to less downtime and more work done.

Also, automation and IoT help us use tools for predicting when pumps might fail. These tools help us see trends that show when a pump might need fixing. This way, we can keep our pumps running well.

By investing in these systems, we make our pump operations more reliable and productive.

Training Personnel for Effective Pump Management:

Effective pump operation depends on the skills of those who manage them. It’s key to invest in good pump training programs. This ensures team members know how to operate, follow safety rules, and fix issues.

Well-trained staff can cut down on downtime and make pumping systems more reliable. I make sure my team has the right skills for the job.

My team learns about pump mechanics and the need for regular maintenance. They also learn how to solve problems quickly. This makes our pumps more reliable and efficient.

Utilizing Technology for Pump Health Checks:

Technology is key in keeping pump systems running smoothly. I’ve seen how tools like ultrasound and pressure sensors make a big difference. They help find problems early, stopping small issues from becoming big ones.

Ultrasound technology checks bearings and seals in real-time. It spots leaks and keeps an eye on lubrication levels. Pressure sensors also track how well the pump is doing. Together, these tools make pumps more reliable and efficient.

Feedback Loops for Continuous Improvement:

Feedback loops are key to making pumps more reliable. They help us collect and analyze data to improve maintenance. By looking at this data often, we spot trends and problems early. This lets us make quick changes to boost performance and reliability.

Using feedback loops helps us see where we can get better and improve processes. It makes teamwork better as everyone shares ideas. This leads to smarter decisions. With real-time data, pumps work their best.

Putting feedback loops first means always looking to get better at managing pumps. Staying focused on analysis and improvement keeps things running smoothly. It makes sure pumps are not just reliable but also work at their best all the time.