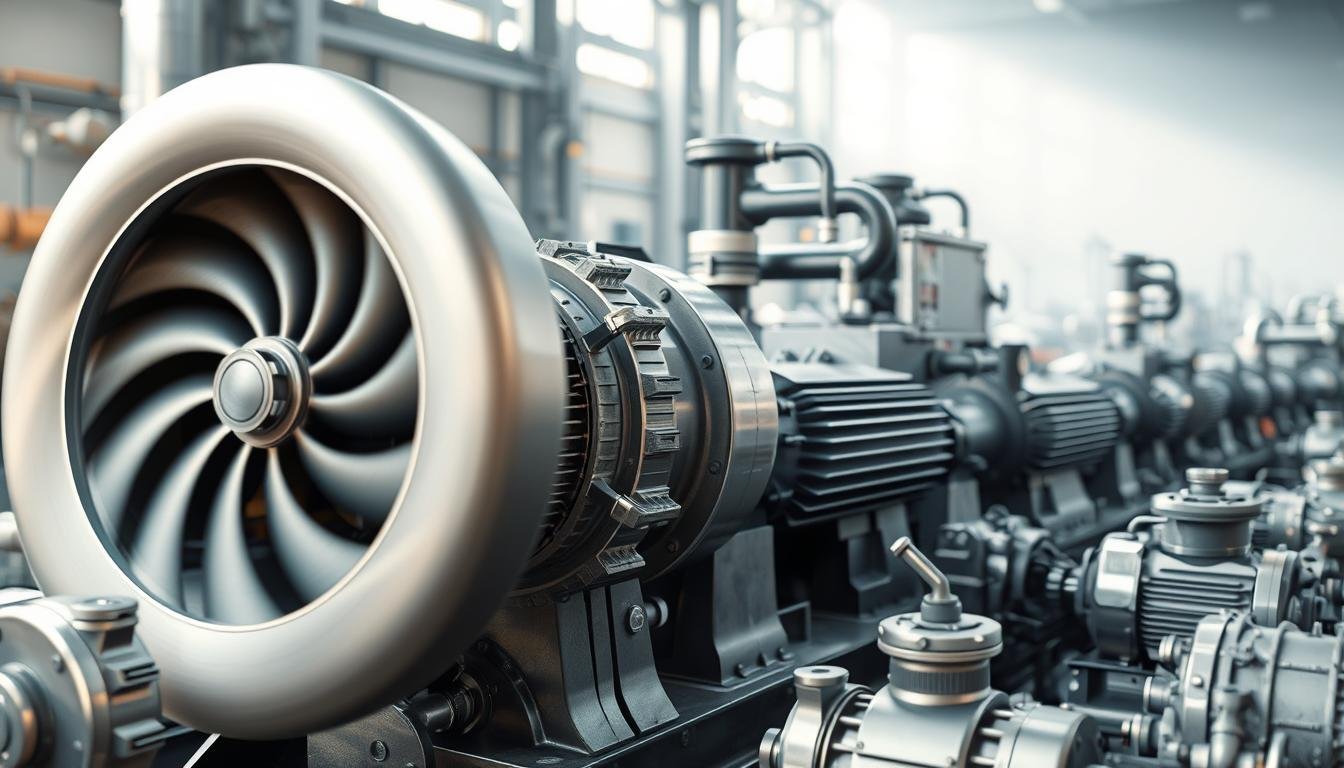

In the world of industrial machinery, pumps, compressors, and turbines are key. They power many processes in different sectors. I want to give you a detailed look at these important parts.

These machines are vital in industries like oil and gas, power generation, and manufacturing. They turn energy into motion. This shows how important they are in today’s industrial world.

Understanding Rotating Equipment:

Rotating equipment is key in many industries. It’s important to know what it is and what it does. This includes things like pumps and turbines that move or generate power.

These machines work by using rotational energy. For example, pumps use it to move fluids. Turbines use it to make electricity. Knowing how they work helps us use and maintain them better.

The Importance of Pumps in Industrial Applications:

Pumps are key in industrial settings, keeping processes running smoothly. They move essential fluids, boosting efficiency and productivity. Knowing about different pumps, like centrifugal and diaphragm, shows their unique benefits in various roles.

Centrifugal pumps are great for handling big volumes of fluid, often seen in water treatment. Diaphragm pumps, on the other hand, are perfect for chemical processing because they handle corrosive substances well. This shows pumps’ importance in many industries, including oil refineries.

Fluid dynamics is vital for pumps’ performance under different conditions. By understanding fluid mechanics, pumps keep working well even with changes in pressure and flow. This knowledge helps make better choices when picking equipment and improving processes.

Compressors: An Overview:

Compressors are key in many fields like refrigeration, air conditioning, and natural gas transport. Knowing the different types is vital for better performance and efficiency. The main types are reciprocating, rotary screw, and centrifugal compressors. Each type has its own way of compressing gases.

Reciprocating compressors use pistons to compress gas, making them good for high-pressure needs. Rotary screw compressors, with their rotating parts, offer smooth operation and reliability. Centrifugal compressors use fast-moving impellers for compression, best for big industrial needs.

Improving compressor efficiency is important today. Regular maintenance, proper sizing, and the right compressor type can save a lot of energy. By optimizing compressors, industries can work better and spend less.

How Turbines Operate:

Turbines, like gas and steam turbines, are key in turning energy into work. It’s important to know how they work to understand their role in making power. Gas turbines burn fuel to make hot gases that spin rotor blades, creating motion. On the other hand, steam turbines use high-pressure steam to turn blades, showing how thermodynamics works.

The way turbines convert energy depends on their efficiency. This efficiency shows how well they turn input energy into work. This is vital for their use in power plants and in space. It’s amazing how better designs have made turbines more efficient, helping them use energy better. Turbines show how engineering and energy production come together.

Key Components of Rotating Equipment:

Exploring rotating equipment, I see the importance of its core parts. Components like rotors, bearings, seals, and shafts are key. They are vital for the design and function of devices like pumps and turbines.

Rotors are essential for the motion that drives the system. Bearings reduce friction, making the operation smoother. Seals stop fluid leaks, keeping the system working right. Shafts are the central axis, helping to transfer energy efficiently.

New materials and designs have improved these parts. Now, we use strong alloys and composites. These advancements help reduce wear and tear, making the parts last longer.

Maintenance Practices for Rotating Equipment:

Implementing strong maintenance strategies is key for smooth operation of rotating equipment. These practices boost reliability and extend the life of parts like pumps, compressors, and turbines. Predictive maintenance is a big help. It uses advanced monitoring to spot problems early, avoiding expensive breakdowns.

Regular checks keep equipment running well. They help find wear and tear on important parts, keeping machinery efficient. A set schedule for these checks improves reliability in many areas. Using both predictive and preventive maintenance leads to better equipment life and efficiency.

Common Failures in Rotating Equipment:

Understanding common failure modes in rotating equipment is key to keeping things running smoothly. Issues like bearing failures, seal leaks, and cavitation in pumps are common. These problems can stop processes and cost a lot of money if not fixed quickly.

Most failures come from bad lubrication, misalignment, or wear and tear. Spotting these problems early helps fix them fast. Regular checks, like vibration analysis and temperature monitoring, help catch issues before they get worse.

Using proactive maintenance helps keep equipment reliable. Regular checks and maintenance plans reduce unexpected downtime. Having skilled people with the right tools helps solve problems quickly, making operations more efficient.

Energy Efficiency in Rotating Equipment:

In my work with rotating equipment, I’ve learned how key energy efficiency is. It helps cut down on costs by reducing energy use. Using variable frequency drives (VFDs) is a great way to save energy. They adjust motor speed to match demand, saving a lot.

Also, designing systems to work better is important. A well-designed system uses less energy, which lowers costs. Regular checks help find and fix inefficiencies, improving performance.

Going green also helps a lot. It makes equipment last longer and saves money. Energy efficiency and sustainability go hand in hand, making operations better and more responsible.

Innovations in Rotating Equipment Design:

Rotating equipment design has seen major leaps forward, thanks to new materials and smart tech. I’ve seen how advanced materials and digital tools like digital twins and IoT devices are changing the game. These tools help keep machines running smoothly and efficiently.

There’s a big move towards using these technologies in daily life. Companies are using new designs to cut costs and boost reliability. They’re also focusing on being more eco-friendly, which is great for the planet and their bottom line.

Rotating Equipment in Automation:

In today’s world, automation has changed how we work. Rotating equipment like pumps, compressors, and turbines are key. They make many industrial tasks better, from making things to creating energy.

These machines are vital for automated systems to work well. For example, pumps keep fluids moving, which is important for making things. Compressors make sure air or gas is at the right pressure. Turbines turn energy into power, showing their big role in automation.

Using automation helps companies work better and save money. Studies show how new tech can really help. As industries keep using new automation, we’ll see even more improvements in how these machines work.

Industry Standards for Rotating Equipment:

In the world of rotating equipment, following industry standards is key. The American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) lead the way. They set the rules for design, making, and using this equipment.

These standards help keep equipment reliable and efficient. They cover pumps, compressors, and turbines. They are essential for quality control.

Knowing these standards helps with following the law. It makes sure all equipment is safe. This safety protects people and keeps the equipment working well.

Putting quality first means less downtime and lower costs. It’s all about making equipment last longer and work better.

Training and Education on Rotating Equipment:

Investing in workforce training is key for those working with rotating equipment. Educational programs give people the basics and advanced knowledge needed. This knowledge helps them operate and maintain pumps, compressors, and turbines well.

There are many educational programs out there, from certifications to on-the-job training. These programs teach workers how to fix problems, do regular maintenance, and find new solutions. By focusing on technical skills, companies can make sure their teams are ready for any challenge.

Training also helps teams and companies perform better. A trained workforce can cut down on downtime and boost productivity. This shows how important it is to invest in education that meets the industry’s needs.

Future of Rotating Equipment:

The future of rotating equipment looks bright, thanks to new technology. Industries are moving towards better efficiency and lower costs. They also aim to reduce harm to the environment.

Automation and data analytics will change how we use pumps, compressors, and turbines. Smart sensors and IoT will make monitoring and maintenance easier. This will lead to better performance and less downtime.

Research is key to meeting today’s sustainability needs. Manufacturers are working on energy-saving designs. These designs must follow strict rules and help reduce carbon emissions.

In short, the future of rotating equipment is exciting. It’s all about innovation and using technology wisely. Staying ahead in this fast-paced world is vital for success. With ongoing research, I’m sure this equipment will keep evolving, helping industries thrive.